Safety Based Limits for the Control of Impurities in Drug Substances and Drug Products: A Review-Juniper Publishers

JUNIPER PUBLISHERS-OPEN ACCESS JOURNAL OF PHARMACY &

PHARMACEUTICAL SCIENCES

Introduction

Paracelsus, the medieval physician, who is often

viewed as the father of modern toxicology, was the first person to

appreciate that "the dose makes the poison". This essentially means that

very toxic materials can be used therapeutically at very low

concentrations and conversely even safe materials can be toxic if

overdosed. This in turn led to Haber's law, which basically states that,

the incidence and/or severity of any toxic effect is dependent on the

total exposure to the toxic agent; that is, the exposure concentration

(c) rate(or dose) multiplied by the duration time (t) of exposure (i.e.

cxt). This law is often utilised in setting exposure limits for toxic

components. The major caveat, is that establishing acceptable daily

intakes (ADIs) for long-term exposures to a toxic substance when only

data from short-term studies are available, does require the use of an

uncertainty or safety factor.

For example, cancer risk estimates are typically

based on the average lifetime daily dose (LDD), which in turn is derived

from the total cumulative exposure, using Haber's law, i.e. cxt. Gaylor

[1]

proposed a modified Haber’s law to better extrapolate safe levels based

on shorter term exposure intervals and this takes the form of:

c3x t=c’3x t'

where c and t are the known safe exposure levels(c)

based on the longer exposure duration (t) and c’ and t' are the

projected safe concentration (c’) based on the pre-defined shorter

exposure duration (t’). Haber’s law is equally germane to impurities as

it is to medicinal products.

Impurities in New Drug Substances and New Drug Products (Ich Q3a/ Ich Q3b)

One of the first international guidance that used

safety based limits for impurities was the international conference on

harmonization (ICH) Q3A [2].

This provided an overview of the typical impurities that were found in

new drug substances and their controls. Impurities were evaluated based

on both chemistry considerations, including "classification and

identification of impurities, report generation, listing of impurities

in specifications, and a brief discussion of analytical procedures";

and safety considerations, including "specific guidance for qualifying

those impurities that were not present, or were present at substantially

lower levels, in batches of a new drug substance used in safety and

clinical studies"

Impurities were further delineated into identified

and unidentified classes, both of which were included as specification

tests [3].

This includes unidentified impurities that were known to be present at

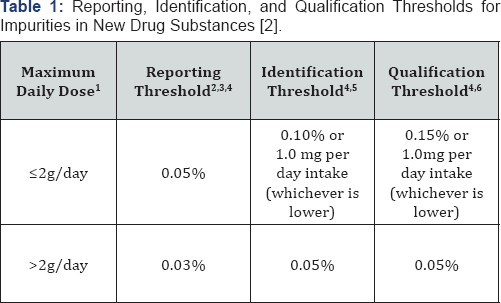

levels greater than pre-defined reporting, identification and

qualification threshold (Table 1).

Those unidentified impurities are often defined on the drug substance

specification "by an appropriate qualitative analytical descriptive

label (e.g., "unidentified A", "unidentified with relative retention of

0.9")"

1. The amount of drug substance administered per day;

2. Reporting Threshold: A limit above (>) which an

impurity should be reported. Reporting threshold is the same as

reporting level in Q2B (4);

3. Higher reporting thresholds should be scientifically justified;

4. Lower thresholds can be appropriate if the impurity is unusually toxic;

5 Identification Thresholds: A limit above (>) which an impurity should be identified;

6 Qualification Thresholds: A limit above (>) which an impurity should be qualified

The reporting threshold was linked to the capability of the supporting analytical methodology [4].

Identification threshold was the limit where the unknown impurity was

required to be identified by appropriate analytical methodology.

Whereas, the qualification threshold necessitated acquiring and

evaluating pre-clinical safety data that "establishes the biological

safety of an individual impurity or a given impurity profile at the

level(s) specified".

Interestingly, although the derivation of the

reporting threshold was linked to method capability, the derivation of

the identification and qualification threshold limits were never fully

delineated, apart from linkage with the maximum daily dose of the

product. In addition, for those impurities "known to be unusually potent

or to produce toxic or unexpected pharmacological effects, the

quantitation/detection limit of the analytical procedures should be

commensurate with the level at which the impurities should be

controlled". Again, the implicit meaning of this statement was never

fully articulated, but it was the genesis for the subsequent guidance on

mutagenic impurities, initially termed genotoxic impurities [5].

Similar guidance was provided for impurities

typically found in new drug products. These impurities are usually

termed degradation products [6]. There was greater delineation of the thresholds in terms of dose (Table 2).

However, it was never fully explained why the various thresholds, in

terms of maximum daily dose, could not be aligned. Thus there is the

confusing scenario that the reporting thresholds are above or below 1g;

whereas, the identification thresholds are divided into four (>2g,

>10mg- 2g, 1mg-10mg and <1mg); whilst the qualification thresholds

were also divided into four, but were not aligned with the classes

defined in the identification thresholds (>2g, >100mg-2g, 10mg-

100mg and <10mg).

1 The amount of drug substance administered per day;

2 Thresholds for degradation products are expressed

either as a percentage of the drug substance or as total daily intake

(TDI) of the degradation product. Lower thresholds can be appropriate if

the degradation product is unusually toxic;

3 Higher thresholds should be scientifically justified.

The other confusing aspect was that the maximum daily

dose (mg/day) and the maximum strength of a product (mg) are often not

the same value. Thus for instance, the anti-malarial drug quinine

sulfate [7]

has a maximum therapeutic dose from the product label of 648mg every

8hours, i.e. 1944mg/day; whereas, the highest dose strength are

324mg/capsule. The analysts testing and releasing quinine sulfate

capsules will do so on the commercial product (324mg/capsule), not the

maximum dose taken by the patient (1944mg/day). In addition, although

reporting thresholds are always measured as percentage values and are

easily aligned with the data output from the method used by the analyst;

identification and qualification thresholds are measured in either

percentage values or mg/day values (Table 3).

The other aspect of having safety based limits for

impurities is that it does not reflect the duration of treatment use for

that drug and results in the same limits being proposed irrespective of

whether the drug is proscribed pro ne rata (PRN) or as required,

e.g. for constipation, mild pain, etc., or through life time

treatments, e.g. for treatment of high blood pressure, etc. ICH Q3A [2] and Q3B [6]

were always intended to be only applicable to marketed products, but

the regulatory expectations during clinical development often exceed

what is actually required. For example, it isn't unusual to see the

following expectations [8]: "For phase I expect structure (or identifier) and

origin For phase II expect Limit of Detection and Quantification and

actual impurity levels to be established (aligned with ICH Q3A, Q3B,

etc)".

However, by phase II the final synthetic route and

process of the drug substance are rarely identified or optimised, and

the attrition rate of phase II drugs is still very high [9]. What the regulatory guidance enshrined in ICH M3 [10],

actually states with respect to impurities is, "If specific studies are

warranted to qualify an impurity or degradant, generally these studies

are not warranted before phase 3 unless there are changes that result in

a significant new impurity profile (e.g., a new synthetic pathway, a

new degradant formed by interactions between the components of the

formulation). In these latter cases, appropriate qualification studies

can be warranted to support phase 2 or later stages of development"

Residual Solvent Impurities (ICH Q3C)

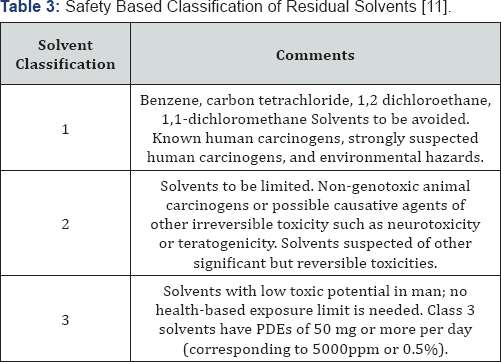

Although residual solvents are mentioned in ICH Q3A [2], a separate guideline, ICH Q3C [11],

was developed to provide safety based guidance on the allowable limits

of common residual solvents within pharmaceuticals. As there are "no

therapeutic benefits from residual solvents, all residual solvents

should be removed to the extent possible to meet product specifications,

good manufacturing practices, or other quality based requirements".

Additionally, ICH Q3C recommends the use of less toxic solvents. Thus,

solvents that are known to be highly toxic (Class 1) should be avoided

during the production of drug substances, excipients, and especially

drug products, unless their usage can be justified using a risk-benefit

assessment [12].

In addition, some solvents with intermediate toxicity (Class 2) should

also be limited from a patient safety perspective. Ideally, the least

toxic solvents (Class 3) should always be used where practical.

Recommended limits for all solvents may change as additional safety data

become available. In addition, supporting safety data for new solvents

may be added to the guidance.

Although tolerable daily intake (TDI) and acceptable

daily intake (ADI) were both in common usage, ICH Q3C (12) introduced a

new term, permitted daily exposure (PDE) to avoid confusion of differing

values for ADI's for the same substance. In addition to avoidance of

class 1 solvents, the concept of "as low as reasonably practicable"

(ALARP) was introduced and is applied to class 2 solvents and often to

class 3 solvents. Indeed, regulatory agencies will often use process

capability arguments to drive down residual solvent levels below the

safety based limits [13] derived from ICH Q3C.

Residual Elemental Impurities (ICH Q3D)

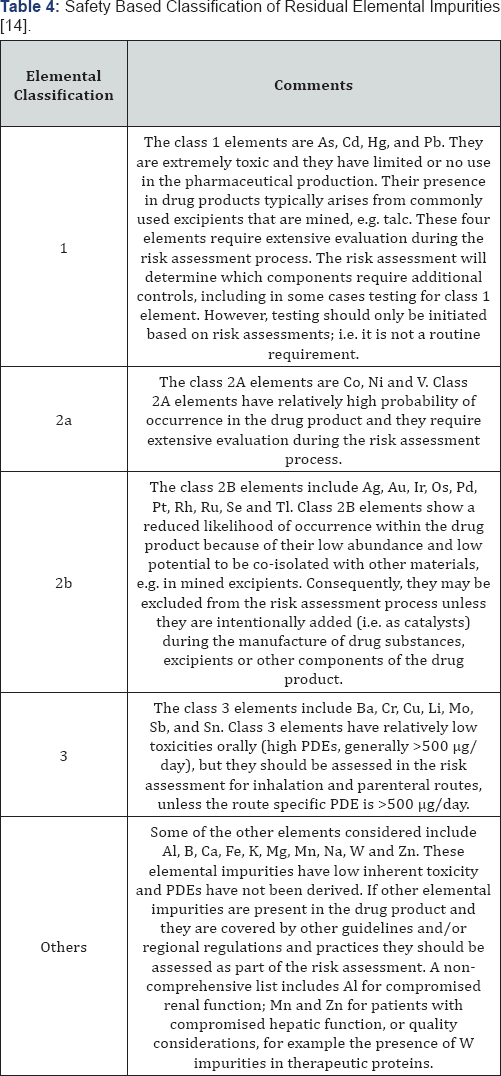

Residual elemental impurities were also mentioned in ICH Q3A [2],

but again a separate guideline, ICH Q3D (14) was developed to provide

safety based guidance on the allowable limits of residual elements

within pharmaceuticals. As elemental impurities provide no therapeutic

benefit to the patient, "their levels in the drug product should be

controlled within acceptable limits" [14].

The ICH Q3D guideline is sub-divided into three

parts: the derivation and assessment of toxicity data; the establishment

of a PDE for each elemental impurity derived for three different routes

of administration (oral, inhaled and parenteral); and application of a

risk based approach to control elemental impurities (as per ICH Q9

(12)). One difference from ICH Q3C [11]

is that applicants are not expected to tighten the safety based limits

based on process capability considerations, as long as the residual

elemental impurities do not exceed the PDE values. However, in certain

cases, levels below the PDE may be warranted when lower levels have been

shown to positively impact on other critical quality attributes (CQAs)

of the drug product; for example, element catalyzed drug degradation

(this is particularly common with oxidative degradation mechanisms [15].

In addition, for those elements with higher PDEs, lower limits may have

to be assessed from a pharmaceutical quality perspective. Residual

elements are classified into 5 different categories: class 1, 2a, 2b, 3

and others (Table 4).

ICH Q3D [14]

provides a platform for developing an ICH Q9 (12) aligned risk-based

control strategy to limit elemental impurities within the drug product.

Although, the guidance had highlighted the risk inherent from both drug

substance and excipients, the reality based on a multi-product

assessment is that the risk is low. Li et al. [16]

tested 190 samples from 31 different excipients and 15 samples from

eight different drug substances for residual elemental impurities. The

results show relatively low levels of elemental impurities are present

in the samples tested.

Residual mutagenic impurities (ICH M7)

ICH M7 [5]

is focused on DNA reactive impurities that can potentially cause DNA

damage, when present at low levels, and thus can potentially cause

cancer in man. Importantly, other types of toxic impurities that are

non-mutagenic will typically have a threshold mechanism and as such

usually do not pose carcinogenic risk in man, at the levels typically

seen for impurities.

A Threshold of Toxicological Concern (TTC) approach

was introduced to describe an "acceptable intake for any unstudied

chemical that poses a negligible risk of carcinogenicity or other toxic

effects", this equates to a virtually safe dose (VSD). The methodologies

that underpin the TTC are universally considered to be very

conservative, as they use a simple linear extrapolation from the TD50 dose (i.e. dose giving a 50% tumor incidence) to a 1 in 106 likelihood of cancer occurrence.

A default TTC value of 1.5μg/day corresponding to a theoretical 10-5

excess lifetime risk of cancer can therefore be justified for mutagenic

impurities. Some high potency groups referred to as the "cohort of

concern", e.g. aflatoxin-like-, N-nitroso-, and alkyl-azoxy compounds;

were identified where the default TTC would still pose a significant

carcinogenic risk. These high potency compounds were excluded from the

TTC approach.

ICH M7 [5] bases acceptable intakes for mutagenic impurities on established risk assessment approaches (see ICH Q9 [12].

As such, acceptable risk during the early development phase is

established at a higher theoretically calculated risk level of

approximately one additional cancer incidence per million, i.e. 1 in 106

risk levels. For later stages in development (Phase III) and for

commercial products, the risk level is reduced to one in one hundred

thousand, i.e. 1 in 105 risk levels. It is worth

highlighting, that these risk levels represent a small theoretical

increase in risk when compared to the overall lifetime incidence of

developing cancer in man, which is greater than 1 in 3.

The initial risk assessment is undertaken on the drug

substance synthetic pathway to identify real or potential impurities

that may be reactive and thereby mutagenic in nature. In parallel, the

formulation and manufacturing process are also assessed for the

formation of any reactive degradants (both real and potential), that

could be realistically expected to form during long term, real-time

storage conditions. In silico structure- based assessments, i.e. Derek

Nexus, Sarah Nexus, etc., are used for predicting mutagenicity based

upon QSAR (quantitative structure activity relationships) approaches.

These findings are then reviewed by toxicology experts to provide any

additional understanding as to the relevance of these predictions (both

positive and negative), and in the case of contradictory outcomes to

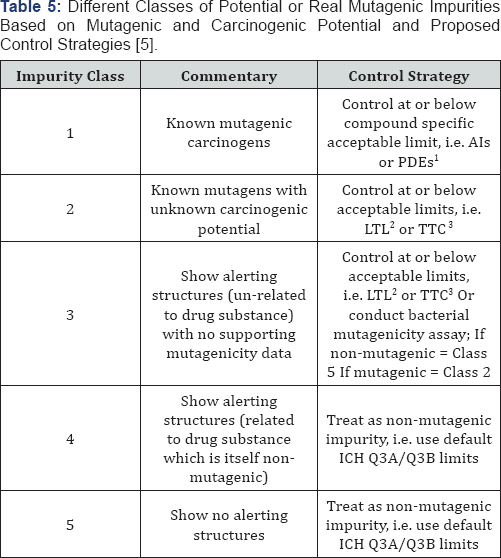

understand those differences. Based on this assessment, impurities are

categorised into five different classes in order of decreasing

regulatory concern (Table 5).

1. For class 1 compounds, i.e. those which are known

mutagenic carcinogens, an AI (acceptable intake) or a PDE (permitted

daily exposure)approach has been introduced (ICH M7(R1) (17)). These

limits are based on either (i) linear extrapolations from TD50 (AI) or

(ii) threshold-based PDEs. There are 10 compounds covered by the AI

approach and a further 3 covered by the PDE approach.

2. LTL (less than lifetime limits)

3. TTC (Threshold of Toxicological Concern)

It is anticipated that monitoring and control

strategies (including analytical methods) will be less developed during

earlier clinical phases, where overall development experience is of

necessity limited, compared to later clinical phases and commercial

manufacture. ICH M7 [17]

proposesa control strategy using four control options for mutagenic

impurities, of these only one includes control of the mutagenic impurity

on the API specification (option 1). Options 2 and 3 define some levels

of in-process control; whereas, option 4 is centred on process

understanding alone, typically termed "Purge Arguments" [18].

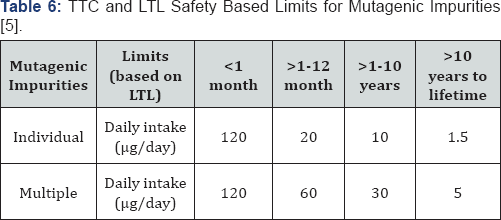

It is should be emphasised that these established

cancer risk assessments are based on lifetime exposures, i.e. 75 years.

Thus, Less-Than-Lifetime (LTL) exposure based limits can be derived both

during development and commercial use. LTLs can have higher acceptable

intakes of mutagenic impurities and still maintain comparable risk

levels, which is obviously an application of Haber's law. Therefore, the

carcinogenic effect is predicated on both duration of exposure and

dose. Thus for example, "if the compound specific acceptable intake is

15 |ig/day for lifetime exposure, the less than lifetime limits (Table 6)

can be increased to a daily intake of 100 |ig (>1-10 years treatment

duration), 200 |ig (>1-12 months) or 1200|ig (<1month)" [5].

This LTL approach may also be appropriate "in diseases with reduced

life expectancy, limited therapeutic alternatives or chronic diseases

with late onset" [19].

It is worth emphasising that exceeding the default

TTC or LTL limits is not necessarily linked with an increased cancer

risk in man, given the extremely conservative suppositions employed in

the evolution and derivation of the TTC or LTL values. For instance,

higher exposure to a potential mutagenic impurity, e.g. formaldehyde,

may be reasonable when exposure can be significantly greater from other

sources, e.g. endogenous metabolism, food, etc. The most likely increase

in cancer incidence is actually much less than 1 in 100,000. In

addition, in cases where a mutagenic compound is a non-carcinogen in a

rodent bioassay, there would be no predicted increase in cancer risk.

Based on all the above considerations, any exposure to an impurity that

is later identified as a mutagen is not necessarily associated with an

increased cancer risk for patients already exposed to the impurity. A

risk assessment would determine whether any further actions would be

taken

In principle, ICH M7 does not apply to advanced

cancer therapeutic indications (covered by ICH S9 (20)), where the drug

is itself genotoxic. ICH M7 does not apply to established excipients,

flavouring agents and certain biological products, including herbal

medicines. Existing commercial products are also exempted, apart from

where there are new safety data (including new mutagenic data) for

existing impurities; significantly, structural alerts alone do not

trigger regulatory concern. However, ICH M7 does cover changes to

marketed products, including new marketing applications and postapproval

submissions.

Impurities in oncology products (ICH S9)

ICH S9 [20]

was developed to provide guidance for nonclinical studies for the

development of anticancer pharmaceuticals used in clinical trials for

the treatment of patients with advanced disease and limited therapeutic

options. During the development of oncology products, supporting

clinical studies often involve cancer patients whose prognosis is poor

and projected lifetime is short (<2 years).

As such, the guideline objectives are to facilitate

and accelerate the development of these anticancer pharmaceuticals

whilst protecting patients from unnecessary adverse effects. In

addition, ethical use of animals, in accordance with the 3R principles

(reduce/refine/replace) are paramount. Importantly, the principles

described in other ICH guidelines need to be considered in the

development of oncology products; whereas, those specific situations

where requirements for nonclinical testing may diverge from other

guidance are described in ICH S9.

Additionally, the dose levels used in these clinical oncology studies are often at the top end of the tolerable range [21]

and often result in adverse effect dose levels. Hence, "the type,

timing and flexibility called for in the design of nonclinical studies

of anticancer pharmaceuticals can differ" significantly from nononcology

pharmaceuticals. Historically, limits for impurities (see ICH Q3A [2] and Q3B [6]

have been based on a negligible risk to the patient. In oncology

products this consideration, whilst important, is not as important as

patient wellbeing and exceeding the ICH Q3A [2]/Q3B [6] limits for impurities may be applicable and an appropriate justification should be included in the marketing application.

This explanation should include an overview of the

disease being treated, including patient prognosis, the nature of the

drug itself (pharmacology, genotoxicity and carcinogenicity, etc.), the

total duration of treatment, and the impact of any reduction in impurity

levels on manufacturability. Furthermore, the qualification of these

impurities may include reflections on the concentration tested in

supporting nonclinical studies compared to the levels seen in clinical

batches. In addition, TTC, LTL and AI/PDE limits for mutagenic

impurities (see ICH M7 [5])

are inappropriate for oncology products and justifications can be used

to set higher limits. Interestingly, the guidance does not specifically

say that the applicant can default to ICH Q3A [2]/ Q3B [6] limits, although this is often inferred. Impurities that are also metabolites can be considered to be suitably qualified.

Interestingly, regulators have been very unwilling to extend the philosophy of ICH S9 [20] beyond oncology products, for instance into rare diseases [22], where lifetime expectancy can be similarly short, i.e. <2 years and where patient expectations are equally high.

New Reflections on Impurities

Harvey et al. [23]

used a variety of chemical databases to demonstrate that the 1mg/day

impurity level for an unqualified impurity of unknown toxicity, proposed

by ICH Q3A [2] (Table 1)

is indeed a robust prediction of a virtually safe dose (VSD) for

non-mutagenic impurities. Then using the modified Haber's law, where C=1

mg and t=75 years (i.e., 27375 days) and t is 6 months or 182 days they

determined a VSD for this shorter exposure interval of 5 mg/day (i.e. 5

times higher than existing ICH Q3A limit). However, for very potent

drugs with effective doses of <1mg, a 5mg/day limit for a related

impurity isn't realistic from either a safety or quality perspective.

Therefore, the authors also introduced a percentage cut off based on 5x

the ICH Q3A qualification threshold of 0.15%; i.e. 0.7%. Thus the

proposed limits for drug substances are 5mg or 0.7%, whichever is lower.

This allows applicants to adopt the existing ICH Q3A

guideline which were developed for commercial products and apply them to

development products, in much the same way that the ICH M7 guidelines

allows LTL limits for mutagenic impurities, for early clinical

development. For drug products, similar LTL limits for non-mutagenic

impurities can be derived based on a modification of Haber’s law. The

additional constraint of a percentage limit of 0.7% need not be applied

to drug products as the more potent the drug substance becomes, the

lower the dose required. The authors therefore suggested a limit of 5 mg

or 2%, whichever is lower, for exposure intervals of <6 months, for

general drug substance impurities, i.e. non-mutagenic.

In addition to absolute amounts of unknown

impurities, the other key focus is those impurities with unusually high

and/ or specific toxicities. Whilst it is recognised that mutagenic

impurities constitute the greatest threat to patient safety and they

have been addressed via ICH M7; there are other classes of non-mutagenic

impurities that will still give cause for concern. The three principal

classes of toxic impurities are

(i) polyhalogenated, dibenzodioxins, dibenzofurans

and biphenyls that are non-mutagenic carcinogens, which have specific

regulatory framework with respect to acceptable exposure levels [24],

(ii) organophosphates or carbamates that are neurotoxins and have their own threshold of concern [25]

and (iii) β- lactam like impurities that have the potential to cause

anaphylaxis and which currently do not have any threshold of concern [23].

It is worth highlighting that

(a) These impurities are extremely rare and do not reflect the typical structure of impurities generated by medicinal research [26,27] and

(b) That these structural motifs (if present) would be highlighted and addressed as part of the ICH M7 risk assessment [5] , as "the findings from any mutagenic risk assessment are also reviewed by toxicology experts"

Conclusion

Safety based impurity limits are a core consideration

of all of the existing ICH Q3 guidance documents. However, there has

been an evolution in the approach toward impurities since the

publication of the initial guidance [2,6]. Whereas, ICH Q3A [2] and Q3B [6]

provide general guidance on impurities in drug substances and drug

products, respectively and mainly focus on absolute levels of

impurities, i.e. percentage based limits; later guidance focused on

individual impurity classes; i.e. residual solvents [11], residual elemental impurities [14] and mutagenic impurities [5]

and had a greater focus on daily exposure limits. In the latter cases,

this led to the introduction of various impurity specific limits, such

as PDEs, Als, TTCs and staged TTCs, all aimed at defining a virtually

safe dose (VSD). This in turn led to the introduction of LTL limits for

mutagenic impurities.

LTLs are based on an application of Haber's law which

states that concentration and exposure times are both critical for

assessing likely safety risk to patients. Surprisingly, LTLs have not

been applied to the other specific classes of impurities or indeed

general impurities. In order to address this deficiency, Harvey et al. [23] have assessed the underpinning data behind the current "1mg or 1%, whichever is lower" limit in ICH Q3A [2] /Q3B [6],

and they found this to be based on robust science and they proposed an

ancillary LTL for general impurities of 5 mg or 0.7%, whichever is

lower, for clinical studies with durations of less than 6 months.

Logically, the toxicity of the parent drug substance

also affects how we deal with impurities, even very toxic impurities.

Thus, there is limited, if any, additional impact on patient safety for

impurities where the parent drug substance is mutagenic, carcinogenic or

cytotoxic. Accordingly it was recognised that for oncology products,

impurity levels (even mutagenic impurities) could be controlled at

higher levels. This "higher level" wasn’t defined but is based on an

overview of the disease being treated, including patient prognosis, and

the nature of the drug itself. Additionally, from a risk based

perspective and an understanding of Haber's law, an overt focus on

impurity control makes little sense if the life expectancy of the

affected patient is short, i.e. less than 2 years [20].

Interestingly, there has been little regulatory appetite for widening

this entirely pragmatic approach to impurity control to other

therapeutic areas, where life expectancy is equally short, i.e. rare

diseases [22].

For more Open Access Journals in Juniper

Publishers

For more articles in Global Journal

of Pharmacy & Pharmaceutical Sciences please

Comments

Post a Comment