Formulation and Evaluation of Solid Dispersion of Glimepiride into Sustained Release-Juniper Publishers

JUNIPER PUBLISHERS-OPEN ACCESS GLOBAL JOURNAL OF PHARMACY & PHARMACEUTICAL SCIENCES

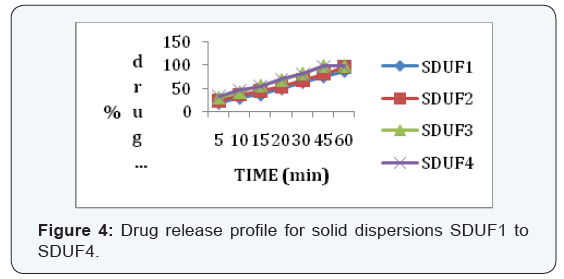

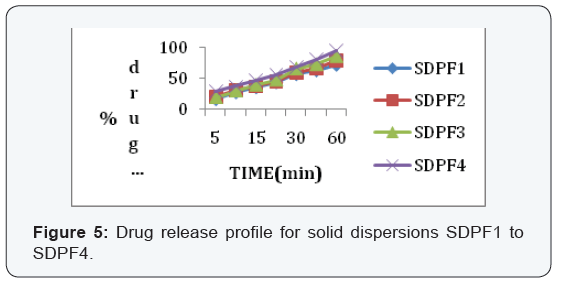

A sustained release tablet containing Glimepiride was

formulated by using solid dispersion technique. Solid dispersions of

glimepiride were prepared by using Urea and PEG 6000 as carrier in drug:

carrier 1:1, 1:2, 1:3, 1:4 ratios by Fusion method. From these all

solid dispersions formulation SDUF3 containing Urea shows better

dissolution compared to other solid dispersions. This optimized solid

dispersion is formulated into sustained release tablets by direct

compression method using hydroxy propyl methyl cellulose and Ethyl

cellulose polymers.

Keywords: Solid dispersion, Diabetes mellitus, Sustained drug releaseAbbreviations: PVP: Poly Vinyl Pyrrolidone; HPMC: Hydroxy Propyl Methyl Cellulose; FTIR: Fourier Transform Infra Red; MCC: Micro Crystalline Cellulose

Introduction

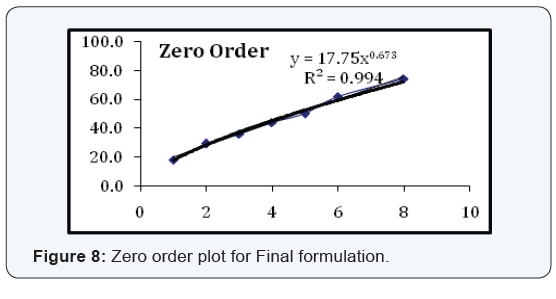

The objective of sustained release [1] dosage form is

to preserve therapeutic blood or tissue levels of the drug for an

extended period. This is commonly accomplished by attempting to gain

zero order release [2] from the dosage form. Zero order release

establishes drug release from the dosage form that is autonomous of the

extent of drug in the delivery system (a constant release rate).

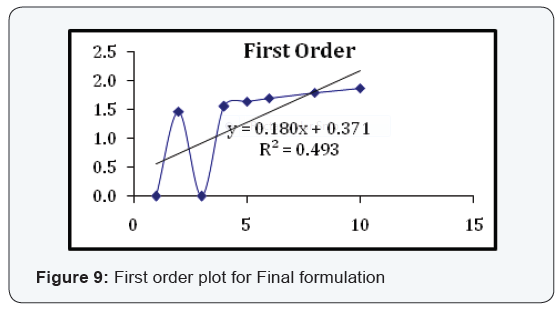

Sustained release system in general do not achieve this form of release

and regularly try to simulate Zero order release given that drug release

is in a slow first order manner (concentration dependent).Systems that

are selected as prolonged release can also be measured as efforts at

attaining sustained release delivery. Repeat-action tablets [3] are an

another techniques of sustained release in which several doses of the

drug are confined within a dosage system, and each dose is free at a

episodic interval. Delayed release system in difference, is usually not

sustaining. Generally, the release rate of drug is not changed and does

not effect in sustained delivery once drug release has commenced. The

word solid dispersion [4] denotes a group of solid products comprising

of a minimum two diverse constituents, largely a hydrophilic matrix and a

hydrophobic drug. The matrix can be any crystalline or amorphous. The

drug could be disseminated molecularly, either in amorphous state or in

crystalline state furthermore, it is the preparation method but not the

molecular arrangement which determines the properties of solid

dispersions.

Methods of Preparation of Solid Dispersions

Melting method

The melting or fusion method [5], comprises the

preparation water-soluble carrier and physical mixture of a drug and

then heating it directly until it reaches a melting point. Then in an

ice –bath with vigorous stirring the melted mixture is solidified. Then

in the final stage the solid mass is crushed, pulverized and sieved.

Solvent method

In the solvent method [6], in a common solvent the

physical mixture of the drug and the carrier are mixed together, and

then evaporated till a clear, solvent free film is left. Then the film

is additionally dried to constant weight.

a. Diabetes mellitus: [7] or only

diabetes, is defined as where a person has high blood sugar, either the

cells do not respond to the insulin, or the pancreas do not produce

enough insulin.. This high blood sugar is characterised by polyuria

(frequent urination), polydipsia (increased thirst) and polyphagia

(increased hunger) [8].

b. Type 1 diabetes: mellitus [9] is

described as loss of the insulin-producing beta cells in the pancreas,

which leads to insulin deficiency. The common of type 1 diabetes is of

immune-mediated nature, where beta cell loss is mediated by T-cell

autoimmune attack. There is no certain precautionary measure against

type 1 diabetes, which is responsible for 10% of diabetes mellitus cases

in North America and Europe. When onset occurs affected people

are healthy and with healthy weight. In the early stages sensitivity

and responsiveness to insulin are generally normal.

c. Type 2 diabetes: Type 2 diabetes mellitus [10] is described

as resistance to insulin where it is combined with fairly decreased

insulin secretion. This is said to involve the insulin receptor. This

is the most common of types.

d. Gestational diabetes: Gestational diabetes mellitus (GDM)

[11] bear a resemblance to in most of the aspects, with decreased

insulin secretion and its response. It is seen in 2-3% of pregnancies

and it may improve or disappear after pregnancy which is

completely treatable. This may require medical observation

during the pregnancy period.

e. Other types: Prediabetes [12]. Is a state where the person’s

glucose levels are higher than the normal but cannot be diagnosed

for type 2diabetes? Persons who develop diabetes type 2 spend

most of their years in Prediabetes state which is termed as

“America’s largest healthcare epidemic” [13]. Latent autoimmune

diabetes of adults (LADA) [14] is a condition which develops in

adults and is of type 1. The aim of the present investigation was

to develop and evaluate a direct compressed sustained release

tablets developed by solid dispersion technique. The tablet

investigated in the current study consists hydroxyl propyl methyl

cellulose which helps in the sustained release of the tablet. Solid

dispersion prepared by using urea showed better dissolution rate

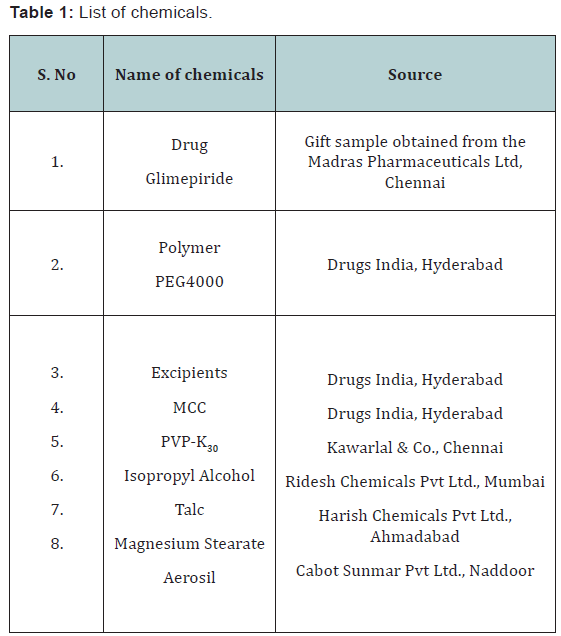

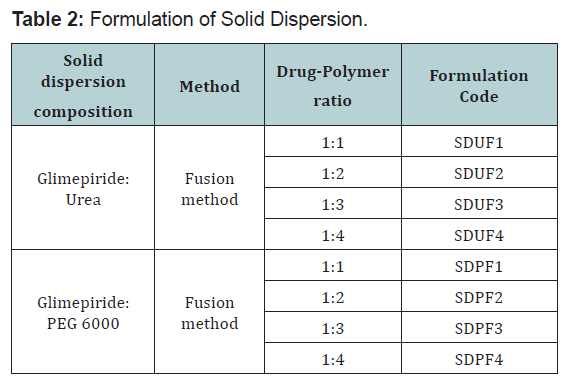

than with PEG6000 (Table 1&2).

Physical mixture of Glimepiride with the combination of PEG

6000 was prepared thoroughly by mixing the accurately weighed

amount of drug and polymer in glass motor and pestle for 5

minutes and sieved through 0.25mm sieve (#60) and stored in

desiccators for 24hours for further studies.

Preparation of solid dispersion by fusion method

Physical mixtures were melting in water bath with gradual

increasing temperature up to the value necessary for the

complete melting. The molten mass was rapidly cooled with

constant stirring with a glass rod. The resulting solid dispersion

was stored in desiccators for 24hrs,after then the prepared solid

dispersion was grounded in motor for 2min ,and passed through

0.25(#60) mesh and used for further studies. Solid dispersion

into sustained release Glimepiride tablet is prepared through

wet granulation method [7] accordingly. Steps like sieving, dry

mixing, preparation of binder solution, granulation and drying are

involved. This preparation was passed through no.20 sieve. Solid

dispersion of glimepiride, HPMC, Ethyl cellulose and MCC were

mixed thoroughly in a poly bag to ensure uniform mixing with the

drug for 5 minutes. 9mg of PV K-30 is weighed accurately and then

mixed with IPA to form a binder solution which was added slowly

to the dry mix to form uniform granules. The wet granules are

then dried by air drying as IPA is corrosive and gets evaporated

quickly. The dried samples are removed at random at regular time

intervals and then passed through sieve no.20 and lubrication was

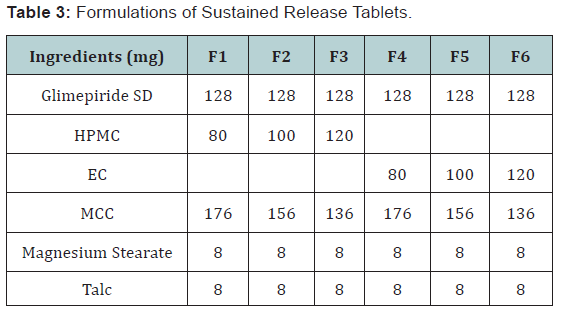

done (Table 3).

Results and Discussion

Analytical methods

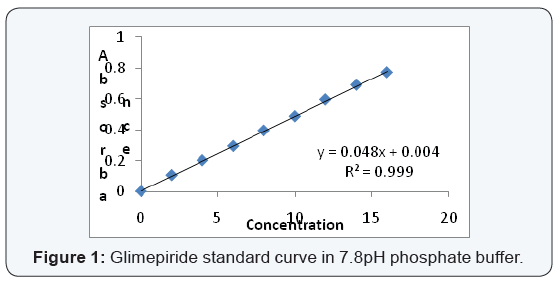

From the standard stock solution (1000 μg/ml), appropriate

aliquot were transferred to series of 10 ml volumetric flasks and

made up to 10 ml with desired solvents so as to get concentration

of 5,10,15,20… or 2,4,6,8… μg/ml. the absorbance of the solution

were measured at 230 nm for Glimepiride. This procedure was

performed in triplicate to validate calibration curve and a graph

is plotted (Figure 1).

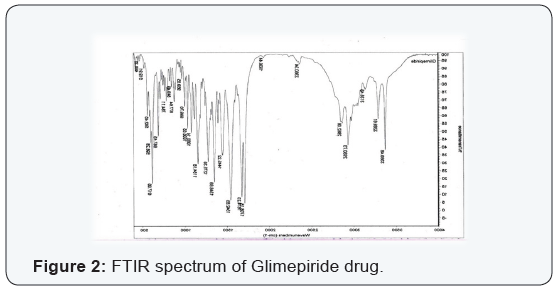

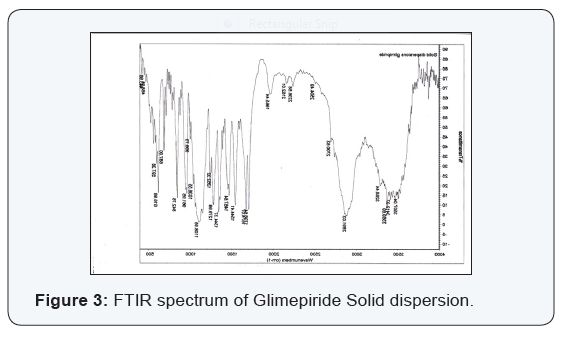

Compatibility studies

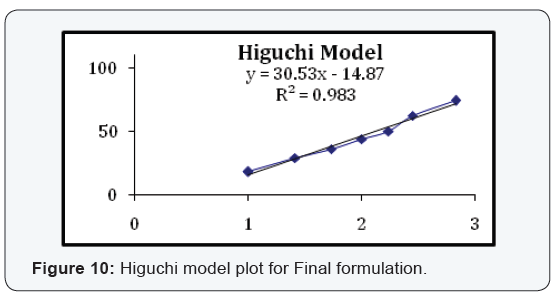

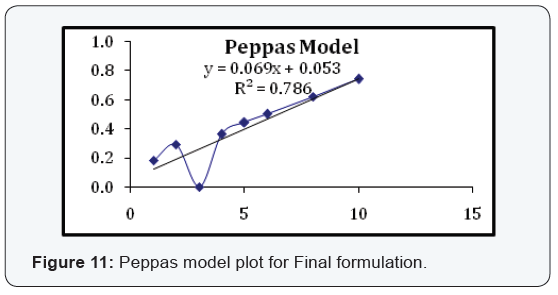

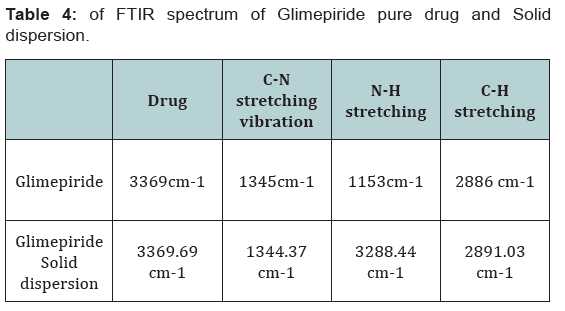

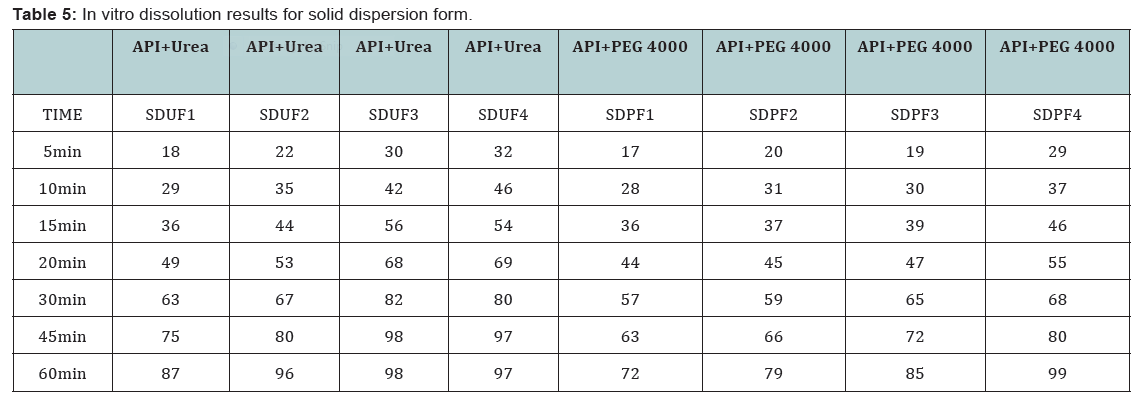

FT-IR spectroscopy is employed to establish the compatibility

of drug with polymer and individual drug. Both the spectra were

compared for confirmation of common peaks. Glimepiride with

polymers showed no significant variation in height, intensity

and position of peaks, suggesting that drug and recipients were

compatible. Interaction between drug and polymer has not been

established. Hence it can be determined that the drug is in Free

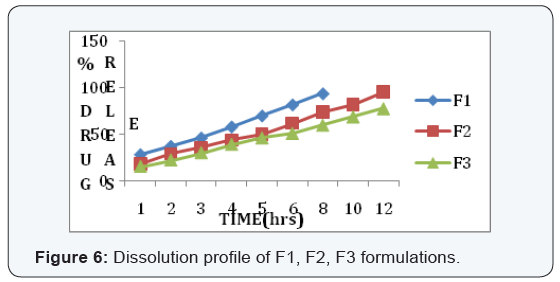

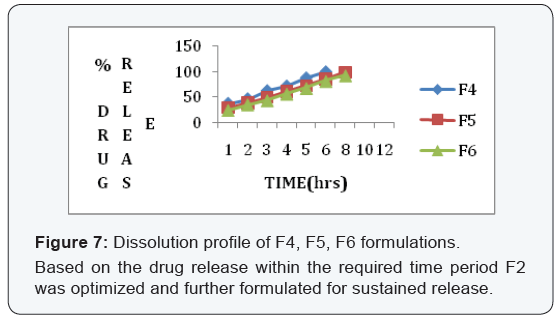

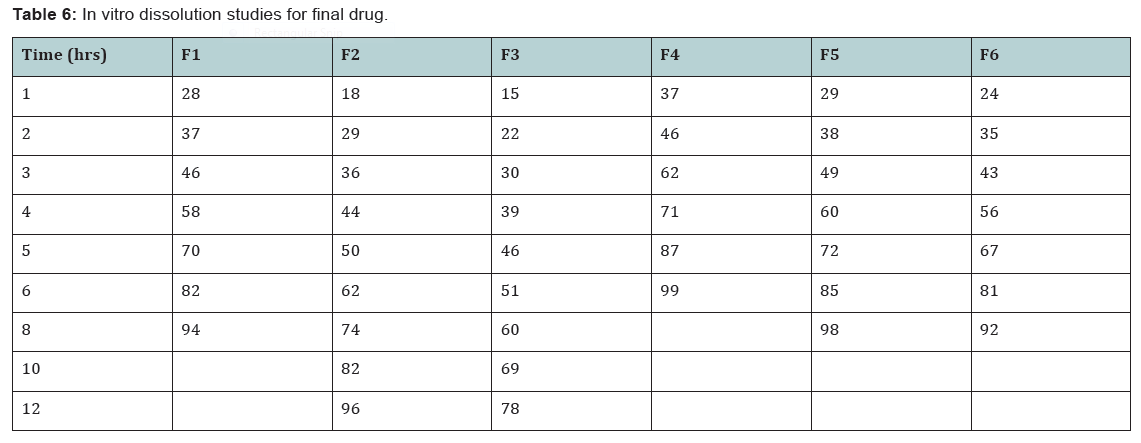

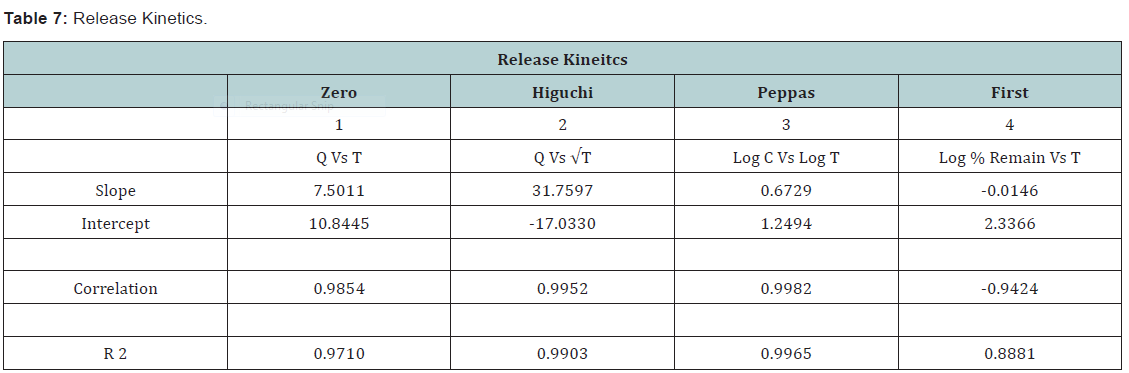

State and can be released easily (Figure 2-11), (Tables 4-7).

Conclusion

In the 6 trials, the optimized formulation was F2 which

releases the drug Glimepiride in a sustained fashion up to 12

hours with96% of drug release.

For more articles in Global Journal of Pharmacy

& Pharmaceutical Sciences please click on: https://juniperpublishers.com/gjpps/index.php

To know more about Juniper Publishers please click on: https://juniperpublishers.business.site/

Comments

Post a Comment