Formulation and Evaluation of Chronomodulated Drug Delivery of Montelukast Sodium--Juniper Publishers

JUNIPER PUBLISHERS-OPEN ACCESS GLOBAL JOURNAL OF PHARMACY &

PHARMACEUTICAL SCIENCES

An oral press coated tablet containing Montelukast

sodium was formulated with an outer barrier layer of different

compositions of hydrophobic polymer eythyl cellulose and hydrophilic

polymer hydroxyl propyl methyl cellulose. This press coated tablet was

prepared by using direct compression and wet granulation methods in

order to achieve the predetermined lag time.

Abbreviations: EC: Ethyl Cellulose; HPMC: Hydroxy Propyl Methyl Cellulose; FTIR: Fourier Transform Infra Red; SLS: Sodium Lauryl Sulphate; IR: Immediate Release; ChrDDS: Chrono Modulated Drug Delivery Systems; PCT: Press Coated Tablets

Introduction

Controlled drug delivery systems [1] have acquired a

centre stage in the area of pharmaceutical R &D sector. Such systems

offer temporal &/or spatial control over the release of drug and

grant a new lease of life to a drug molecule in terms of controlled drug

delivery systems for obvious advantages of oral route of drug

administration. These dosage forms offer many advantages, such as nearly

constant drug level at the site of action, prevention of peak-valley

fluctuation, reduction in dose of drug, reduced dosage frequency,

avoidance of side effects and improved patient compliance. In such

systems the drug release commences as soon as the dosage form is

administered as in the case of conventional dosage forms. However, there

are certain conditions, which demand release of drug after a lag time.

Such a release pattern is known as pulsatile release [2-5]. The diseases

currently targeted for chronopharmaceutical formulations are those for

which there are enough scientific backgrounds to justify ChrDDS compared

to the conventional drug administration approach. These include asthma,

arthritis, duodenal ulcer, cancer, diabetes, cardiovascular diseases,

hypercholesterolemia, ulcer and neurological diseases [6,7].

If the organization in time of living system

including man is borne in mind, it is easy to conceive that not only

must the right amount of the right substance be at right place but also

this must occur at the right time. In the last decade numerous studies

in animals as well as clinical studies have provided convincing

evidence, that the pharmacokinetics &/or the drug effects -side

effects can be modified by the circadian time &/or the timing of

drug application within 24 hrs of a day [8]. A pulsatile drug delivery

system that can be administered at night (before sleep) but that release

drug in early morning would be a promising chronopharmaceutic system.

Drug targeting to colon [9] would prove useful where intentional delayed

drug absorption is desired from therapeutic point of view in the

treatment of disease that have peak symptoms in the early morning such

as nocturnal asthma, angina, arthritis.

Circadian rhythms are self-sustaining, endogenous

oscillation, exhibiting periodicities of about one day or 24 hours.

Normally, circadian rhythms are synchronized according to the body’s

pacemaker clock, located in the suprachiasmic nucleus of the

hypothalamus [8]. Asthma is a chronic inflammatory disease of the

airways, characterized by hyper responsiveness to a variety of stimuli.

The role of circadian rhythms in the pathogenesis and treatment of

asthma indicates that airway resistance increases progressively at night

in asthmatic patients. Circadian changes are seen in normal lung

function, which reaches a low point in the early morning hours. The

worsening

of asthma at night commonly referred to as nocturnal asthma

(NA) [10]. A drug delivery system administered at bedtime but

releasing drug during morning hours would be ideal in this case.

Nocturnal asthma is a variable exacerbation of the underlying

asthma condition associated with increases in symptoms, need

for medication, airway responsiveness, and/or worsening of lung

function. Generally, a reduction in peak flow or forced expiratory

volume in one second (FEV1) of at least 20% is implicit in this

definition. Lung function (e.g., peak expiratory flow rate or

FEV1) is usually highest at 4 PM and lowest at 4 AM the latter

time is generally when asthma symptoms are most prevalent. .

Consequently, the administration of a drug formulated in such a

delivery system, i.e. taken at bedtime with a programmed start of

drug release in early morning hours, could offer a more effective

therapy than a typical controlled release drug delivery system,

provided that the most appropriate drugs are administrated

[11].

Pharmaceutical coatings [12] are an essential tool to achieve

the desired formulation of pharmaceutical dosage forms. Coating

techniques mostly used in pharmaceutical industry are aqueous

or organic coating, which present some disadvantages: time

consuming, stability for heat labile and hydrolysis of degradable

drug and polluted environment problem. Thereby, non-solvent

coating is introduced as alternative coating technique to overcome these disadvantages.

For the time controlled release system from compressioncoated

tablets, the amount of the outer shell is a key factor for

controlling the lag time. Higher amount of the outer coating

added would prolong the lag time of drug release [13].

The aim of the present investigation was to develop and

evaluate an alternative, simple, orally applicable one pulse drug

delivery system based on a press-coated tablet preparation.

The PCT investigated in the current study consisting of a

rapidly disintegrating core tablet presscoated by a barrier layer

consisting of varying concentrations of Hydroxy propyl methyl

cellulose (HPMC) and Ethylcellulose (EC). HPMC is a disintegrant

and had been used to cause rapid disintegration of tablets. The

other component of the barrier layer, Ethylcellulose (EC) is a

well-known water-insoluble polymer that has long been used

as a rate-controlling membrane in medication dosage forms to

regulate drug release. Although EC has also been added in tablet

formulations to act as a retarding material, few papers have

focused on the use of EC as a directly compressible excipient.

It was postulated that when the barrier layer was exposed to

dissolution media, the HPMC particles swell and erode [14], a

process which was retarded to varying degrees depending upon

the quantity of EC present, demonstrating that manipulation of

both components controls the erosion rate.

Materials and Methods

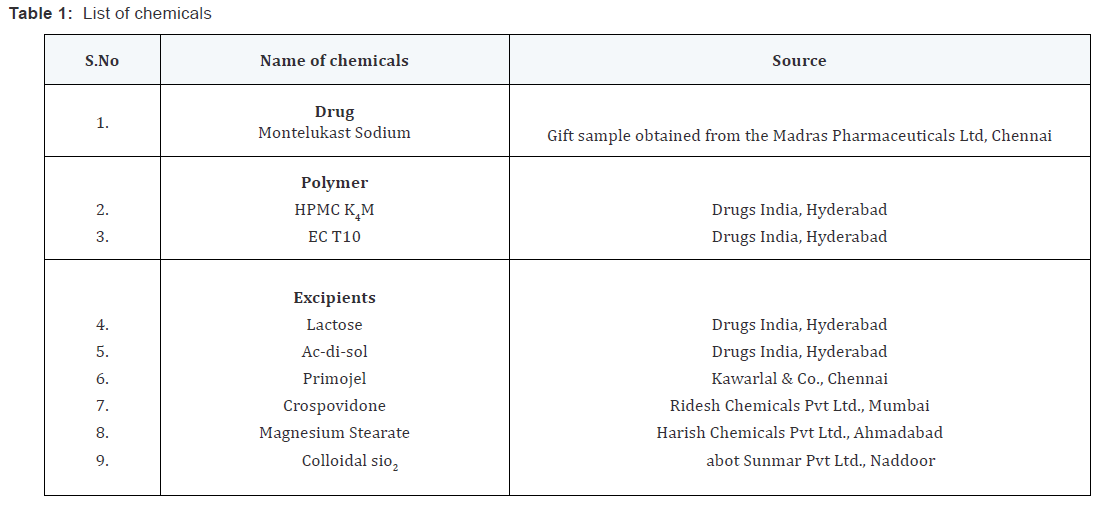

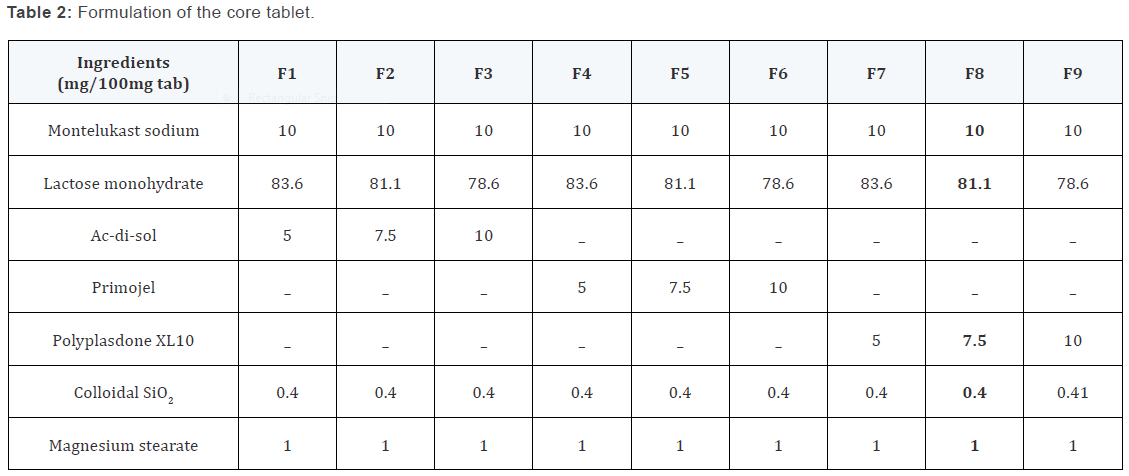

Preparation of core tablets by direct compression

The ingredients depicted in the table except colloidal silicon

dioxide and magnesium stearate were dry blended for 15 minutes

followed by addition of quitted ingredients and dry blended for another 5 minutes. The mixed blend of drug and excipients was

compressed using a single punch CADMACH punching machine

to produce round tablets weighing 100mg with a diameter of

6mm. A minimum of 50 tablets were prepared for each batch.

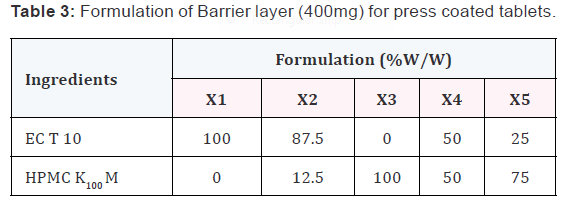

Preparation of press-coated tablets

The core tablets were press-coated with 400mg of prepared

barrier blend as per the mentioned formulas from X1 to X5.

200mg of barrier layer material was weighed and transferred

into a 13mm die then the core tablet was placed manually at the

center. The remaining 200mg of the barrier layer material was

added into the die and compressed.

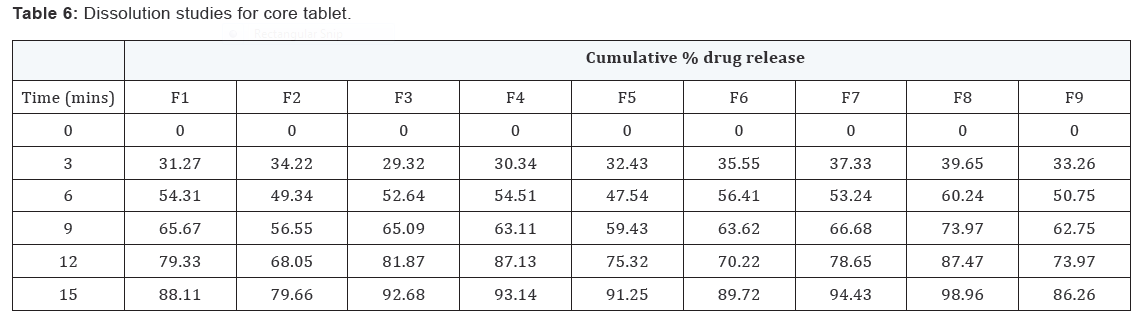

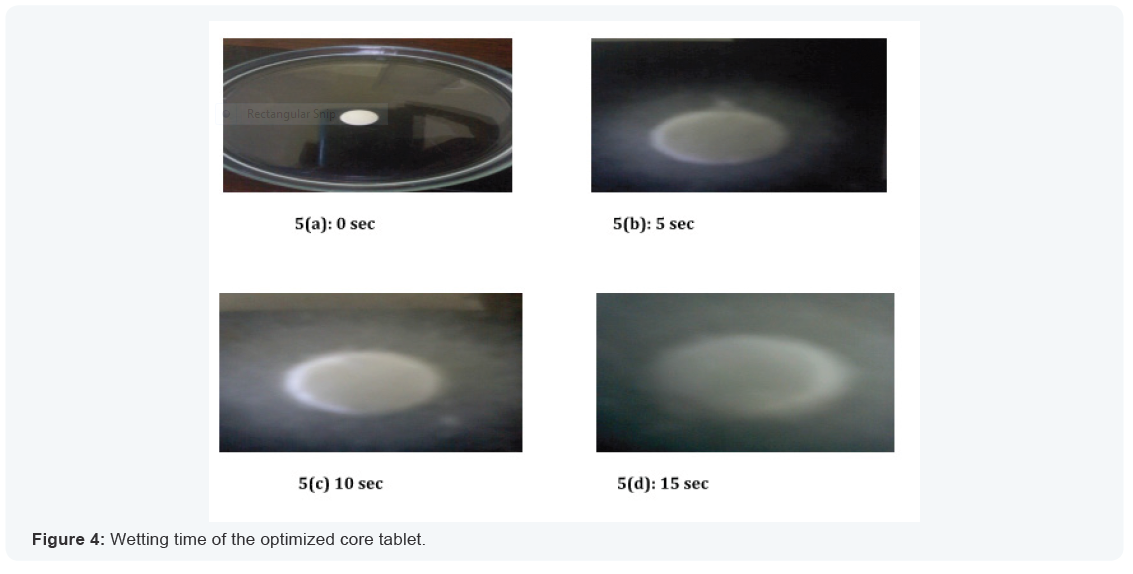

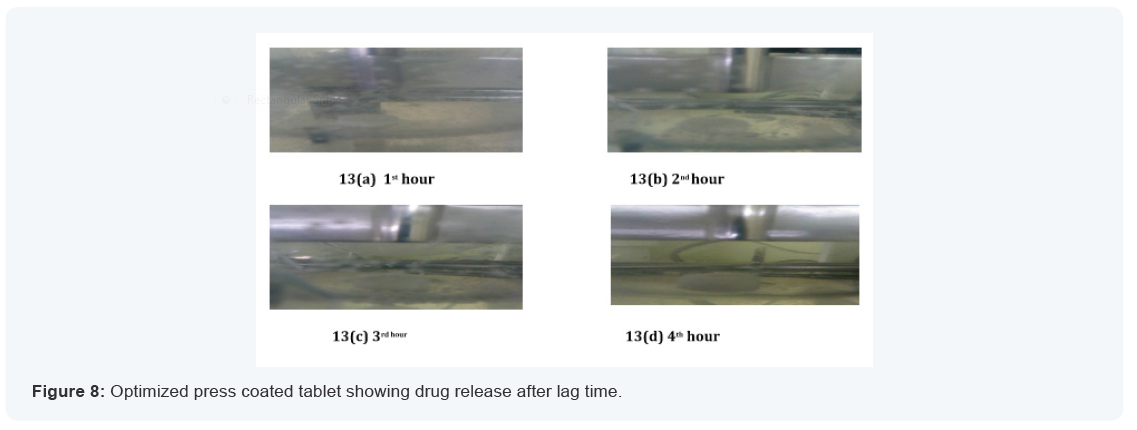

In vitro drug release study of core tablets

The In vitro release pattern of core tablets was studied as per

method given by Chaudhari SP [15] Release pattern was studied

visually by taking images of the core tablets in a petri plate

containing dissolution medium at the specific time intervals

5sec, 10sec, 15sec. Also the sample was analyzed at 342nm using

a UV spectrophotometer.

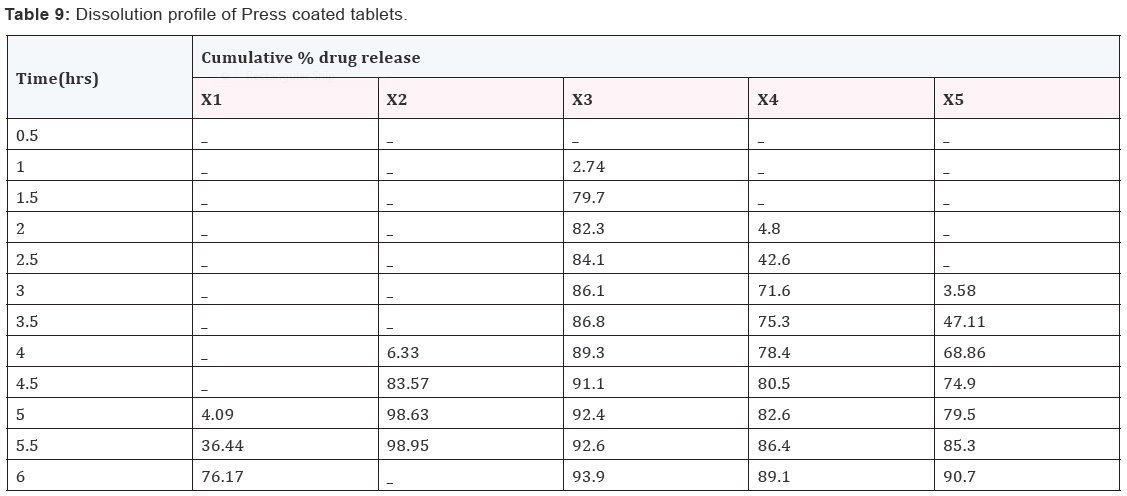

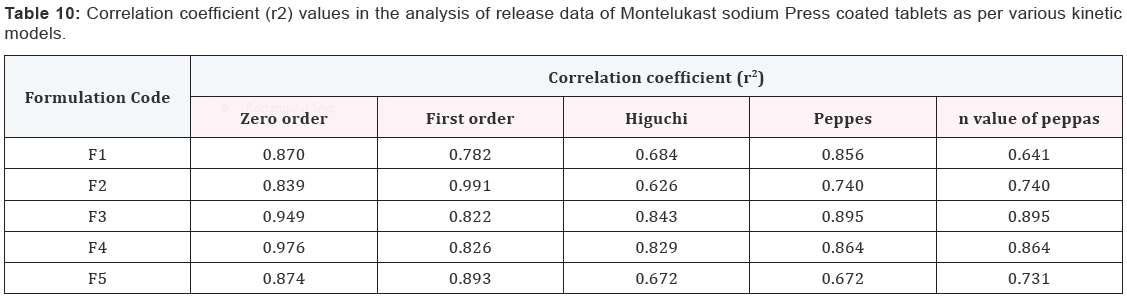

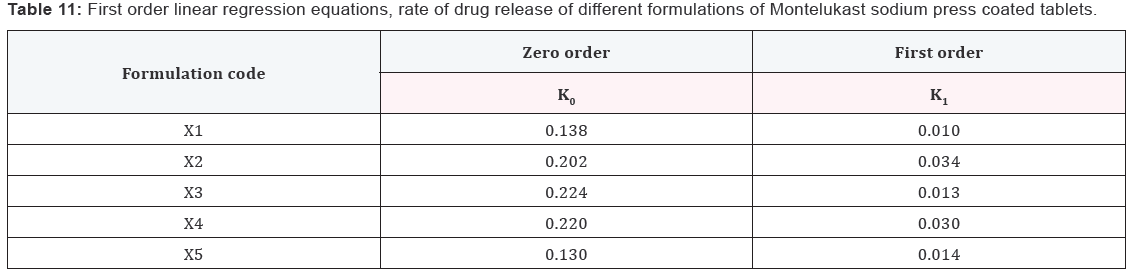

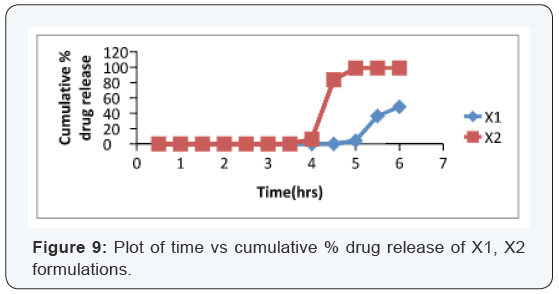

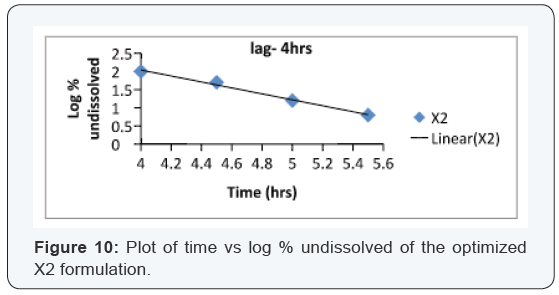

In vitro drug release study of press-coated tablets

In-vitro dissolution studies of press coated tablets were

performed at 37 ± 0.5 °C using 0.5% w/v aqueous solution

sodium lauryl sulfate in USP II paddle method at 50 rpm. 5 ml

of filtered aliquot was manually withdrawn at pre-determined

time intervals and replaced with 5 ml of fresh 0.5% sodium

lauryl sulfate solution maintained at the same temperature. The

samples were analysed at 342nm using a UV spectrophotometer.

The lag time and percentage release was determined of the each

formulation.

Results and Discussion

Design of Pulsatile release tablet

The pulsatile drug delivery system consisted of inner core

tablet containing drug reservoir and outer coating layer with

combination of water insoluble polymer Ethylcellulose and water

soluble polymer HPMC. Ethyl cellulose was chosen because of its

swelling and rupturable behavior. HPMC was chosen because of

its eroding behavior.

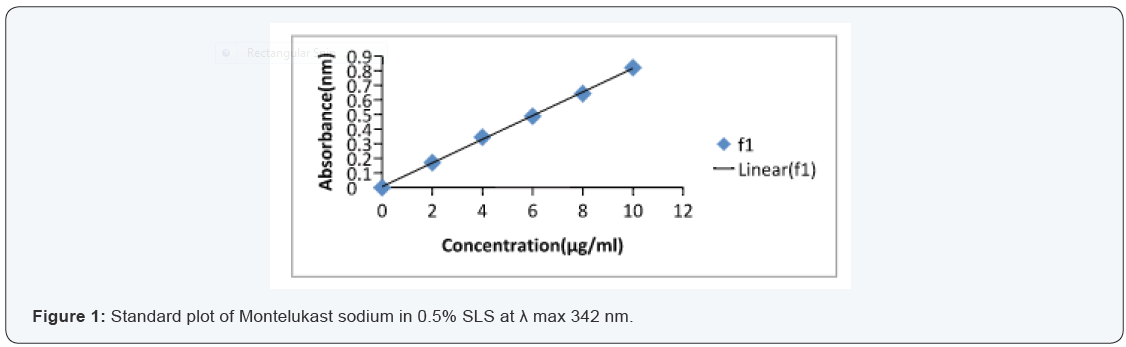

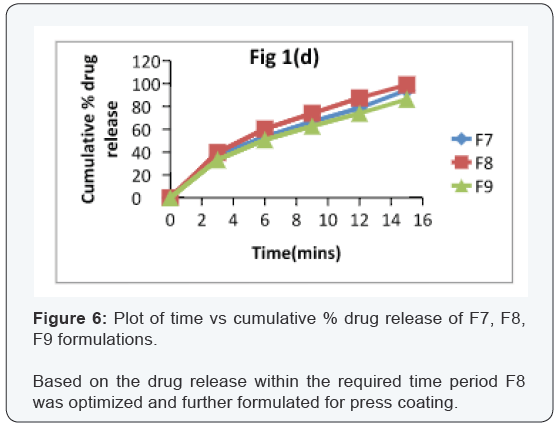

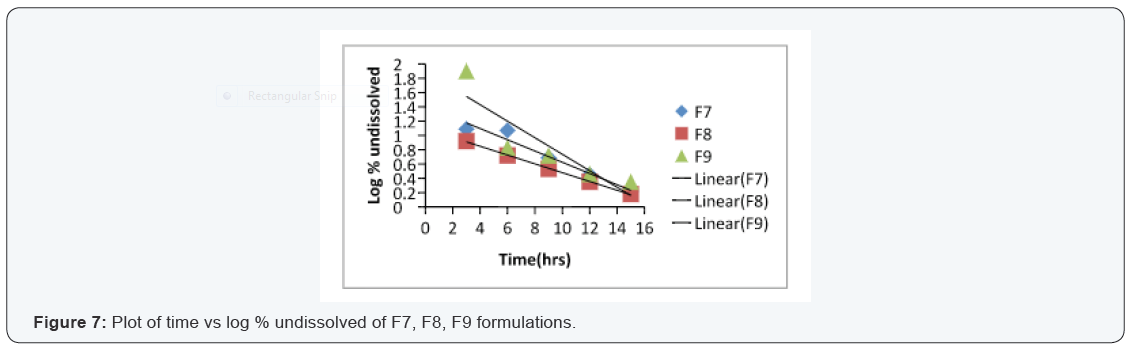

In vitro dissolution of core tablets

The core tablet shows 73.97 % of drug release within 9

minutes upon contact with dissolution medium, core tablet get

erode and release the drug as given in Figure 1.

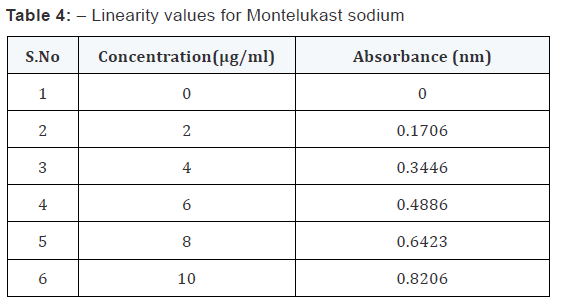

Analytical methods

From the standard stock solution (1000 μg/ml), appropriate

aliquot were transferred to series of 10 ml volumetric flasks and

made upto 10 ml with desired solvents so as to get concentration

of 5,10,15,20… or 2,4,6,8… μg/ml. the absorbance of the solution

were measured at 342 nm for Montelukast sodium. This

procedure was performed in triplicate to validate calibration

curve. A calibration curve was plotted.

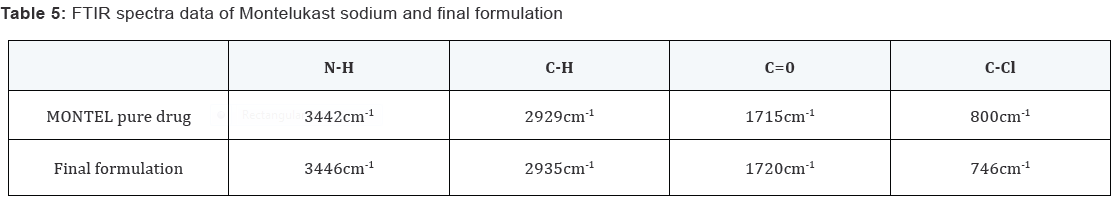

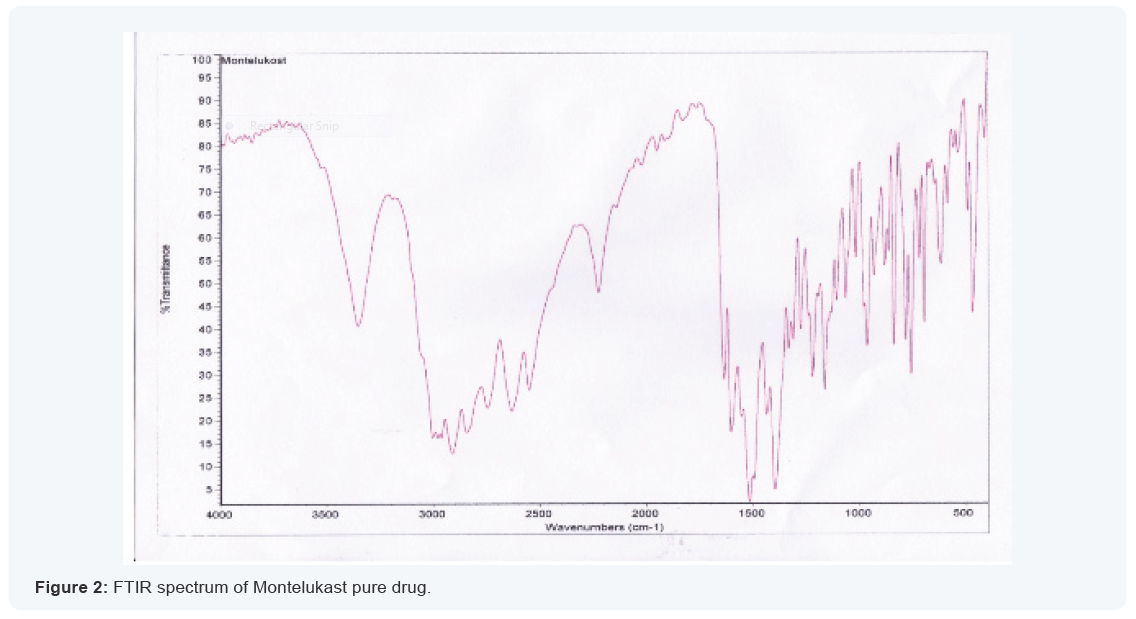

Compatibility Analysis

Fourier transform infra-red spectroscopy

FT-IR spectroscopy was employed to ascertain the

compatibility of drugs with polymers. The individual drug and

final formulation were scanned. Both the spectra were compared

for confirmation of common peaks. Montelukast sodium with

polymers showed no significant variation in height, intensity

and position of peaks, suggesting that drug and excipients were

compatible. There is no interaction between drug and polymer.

Hence, it can be concluded that the drug is in Free State and can

release easily from the formulation the spectra are reported in

the Table no.6.3 and Figure 6.2-6.3.

For more articles in Global Journal of Pharmacy

& Pharmaceutical Sciences please click on: https://juniperpublishers.com/gjpps/index.php

Comments

Post a Comment